|

Drag Chain Conveyor

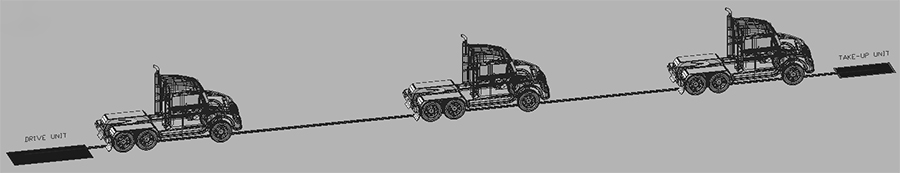

RSI "MAX TOW" Drag Chain Conveyor , using rivetless chain, is able to move a wide variety of products. This provides an ergonomic solution for many heavy applications that would otherwise be very time consuming to perform. This line can be applied to heavy manufacturing for the desired process such as welding, assembly, Finishing, transporting at “creeping speeds” or indexing.

Speeds range from 1 inch per minute to 5 inches per minute constant moving or index mode from work station to work station at higher speeds.

Please contact us for additional information on how we can help you design a Drag Chain Conveyor that will suit your requirements!

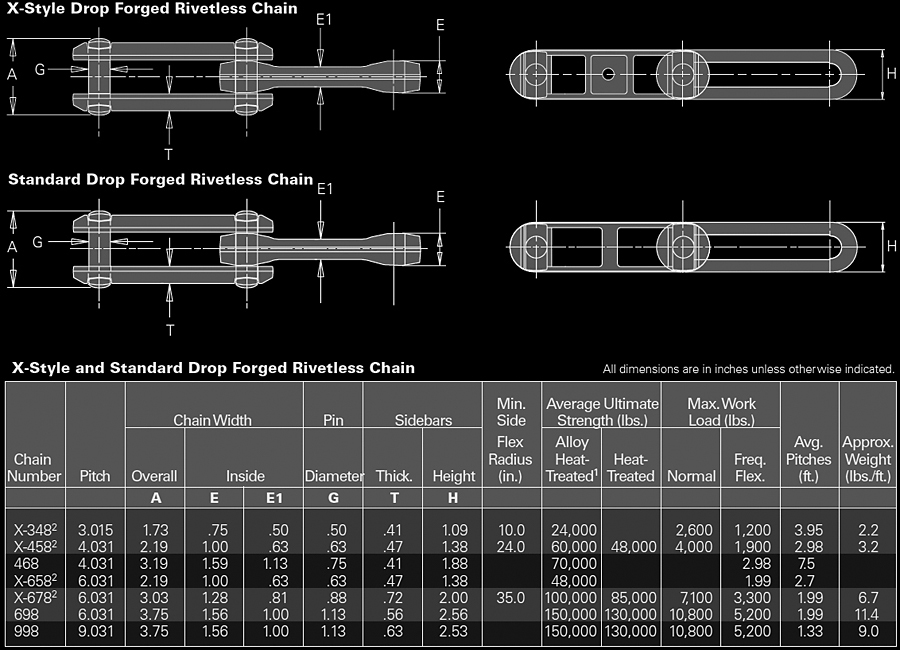

Forged Rivetless Chain has a high strength-to-weight ratio, capability to flex both horizontally and vertically, and ability to be assembled without tools and remain assembled in service, all contribute to make this type of chain the logical choice for long service with minimum maintenance cost. All chain parts are drop steel for maximum strength. Special alloys are available and chain parts can be heat treated and magnafluxed, if required. Pins are placed through the center link and held in position by notches in the side bars when they are installed. Symmetrical design of the pin allows for 180° rotation if new wear surfaces should be required

With this capability, RSI can and will be able to design a system that will be able to carry your product and provide maximum use of your work area.

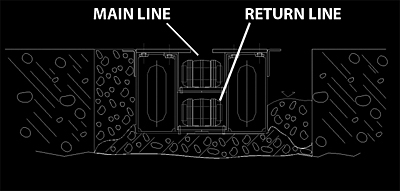

We can and will provide a system that best meets your needs. The RSI Drag Chain Conveyor can be mounted either on-floor or in-floor, for your convenience. RSI designs the conveyor to meet your needs!

Please use the above navigation buttons for more information!

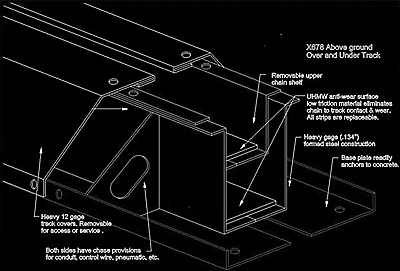

On-Floor Configuration

In-Floor Configuration

Copyright 2005 Rhodes Systems International Incorporated 1350 South 15th Street Louisville KY 40210 PH:502.213.3865 FX:502.213.0096 |